Introduction

Embroidery digitizing has revolutionized the textile industry, transforming traditional needlework into a high-tech art form. This process bridges the gap between ancient craftsmanship and modern technology, allowing for intricate designs to be reproduced with unprecedented precision and efficiency. As we delve into the world of embroidery digitizing, we'll explore its definition, benefits, and the pivotal role it plays in today's embroidery landscape. Join us on this journey to understand how this innovative technique is reshaping the fabric of creativity in the textile world.

1. What is embroidery digitizing?

1.1 Definition and explanation

Embroidery digitizing is the process of converting artwork or designs into a digital format that embroidery machines can read and execute. This intricate process involves translating visual elements into a series of stitches, creating a blueprint for the embroidery machine to follow. At its core, digitizing transforms static images into dynamic, threaded masterpieces.

The art of digitizing requires a blend of technical skill and artistic vision. A digitizer must understand not only the capabilities of embroidery machines but also the nuances of fabric textures, thread types, and design aesthetics. This expertise allows them to create files that produce high-quality, consistent embroidery results.

1.2 Difference between traditional embroidery and digitized embroidery

Traditional embroidery and digitized embroidery represent two distinct approaches to the craft, each with its own unique characteristics and advantages:

-

Execution Method:

- Traditional: Relies on manual skill and hand-eye coordination.

- Digitized: Utilizes computer-controlled machines for precise execution.

-

Design Complexity:

- Traditional: Limited by human dexterity and time constraints.

- Digitized: Capable of intricate, complex designs with consistent quality.

-

Production Speed:

- Traditional: Time-consuming, especially for detailed work.

- Digitized: Significantly faster, allowing for large-scale production.

-

Consistency:

- Traditional: Variations between pieces are common and often valued.

- Digitized: Ensures uniformity across multiple items.

-

Customization:

- Traditional: Each piece is unique, reflecting the artisan's touch.

- Digitized: Easily replicable with options for minor adjustments.

-

Skill Requirements:

- Traditional: Demands years of practice to master.

- Digitized: Requires technical knowledge of software and machines.

-

Cost Efficiency:

- Traditional: Labor-intensive, often leading to higher costs.

- Digitized: More cost-effective for large quantities.

-

Texture and Dimension:

- Traditional: Often has a more tactile, three-dimensional quality.

- Digitized: Can achieve a crisp, uniform appearance.

While traditional embroidery maintains its charm and artisanal value, digitized embroidery has opened up new possibilities in terms of precision, speed, and scalability. This modern approach has made intricate embroidery more accessible and versatile, particularly in commercial and industrial applications.

1.3 Role of technology in embroidery digitizing

Technology plays a pivotal role in embroidery digitizing, transforming the entire embroidery process from design conception to final production. Here's how technology has revolutionized this craft:

-

Design Software:

Advanced digitizing software allows designers to create, edit, and optimize embroidery designs with unprecedented precision. These programs offer features like auto-digitizing, stitch simulation, and 3D visualization, enabling digitizers to refine their work before it reaches the machine. -

Machine Integration:

Modern embroidery machines are equipped with computer-controlled systems that can read and execute digitized designs. This integration ensures that the final product closely matches the digital blueprint, minimizing human error and enhancing consistency. -

Color Management:

Digital technology enables accurate color matching and blending, allowing for more vibrant and complex designs. Software can suggest optimal thread colors and simulate how they will appear on different fabrics. -

Stitch Optimization:

Algorithms within digitizing software can automatically optimize stitch patterns for different fabrics and design elements, reducing production time and improving the overall quality of the embroidery. -

Cloud-Based Collaboration:

With cloud technology, designers and clients can collaborate in real-time, sharing and modifying designs regardless of geographical locations. This streamlines the approval process and enhances communication. -

Machine Learning and AI:

Emerging AI technologies are beginning to play a role in embroidery digitizing, offering features like automatic design suggestions, pattern recognition, and even predicting potential issues in the embroidery process. -

Digital Asset Management:

Large-scale embroidery operations benefit from digital systems that manage vast libraries of designs, ensuring easy access and version control. -

Quality Control:

Digital imaging and analysis tools can inspect finished embroidery, comparing it to the original design to ensure quality standards are met. -

Sustainable Practices:

Technology aids in optimizing resource use, reducing waste by calculating precise thread requirements and minimizing errors that could lead to material waste. -

Customization at Scale:

Digital processes allow for mass customization, enabling businesses to offer personalized embroidery efficiently, even for large orders.

By leveraging these technological advancements, embroidery digitizing has become more efficient, accurate, and versatile. It has opened up new creative possibilities while simultaneously improving production speed and consistency. As technology continues to evolve, we can expect even more innovations in the field of embroidery digitizing, further enhancing its capabilities and applications.

2. Understanding Embroidery Digitizing

2.1 Definition and Process of Embroidery Digitizing

Embroidery digitizing is the art and science of converting artwork into a digital format that embroidery machines can interpret and execute. This process transforms static designs into dynamic, stitch-based instructions, allowing for intricate and precise embroidery on various materials. At its core, digitizing bridges the gap between creative vision and tangible, threaded reality.

The process of embroidery digitizing involves several key steps:

- Artwork Preparation: The initial design is refined and optimized for embroidery, considering factors like size, complexity, and intended fabric.

- Software Input: The prepared artwork is imported into specialized digitizing software.

- Stitch Type Selection: Digitizers choose appropriate stitch types for different areas of the design, such as satin stitches for borders or fill stitches for larger areas.

- Stitch Direction and Density: The digitizer determines the direction and density of stitches to achieve the desired texture and appearance.

- Color Sequencing: The order of thread colors is established for efficient stitching.

- Underlay and Compensation: Underlying stitches are added to stabilize the fabric, and adjustments are made to account for fabric push and pull.

- File Creation: The completed design is saved in a format compatible with embroidery machines.

- Test Stitching: The digitized file is tested on the intended fabric to ensure quality and make any necessary adjustments.

This meticulous process requires a blend of technical expertise and artistic intuition. Skilled digitizers, like those at MaggieFrame, understand not only the capabilities of embroidery machines but also the nuances of different fabrics and thread types. Their expertise ensures that the final embroidered product faithfully represents the original design while maintaining optimal quality and efficiency.

2.2 Traditional Embroidery vs. Digitized Embroidery

The evolution from traditional to digitized embroidery marks a significant leap in the textile industry. While both methods create beautiful embellishments, they differ substantially in approach, efficiency, and capabilities:

-

Design Complexity:

- Traditional: Limited by human dexterity and time constraints.

- Digitized: Capable of intricate, complex designs with consistent quality.

-

Production Speed:

- Traditional: Time-consuming, especially for detailed work.

- Digitized: Significantly faster, allowing for large-scale production.

-

Consistency:

- Traditional: Variations between pieces are common and often valued.

- Digitized: Ensures uniformity across multiple items, crucial for branding.

-

Customization:

- Traditional: Each piece is unique, reflecting the artisan's touch.

- Digitized: Easily replicable with options for minor adjustments.

-

Skill Requirements:

- Traditional: Demands years of practice to master.

- Digitized: Requires technical knowledge of software and machines.

-

Cost Efficiency:

- Traditional: Labor-intensive, often leading to higher costs.

- Digitized: More cost-effective for large quantities.

-

Fabric Compatibility:

- Traditional: Limited by fabric type and thickness.

- Digitized: Adaptable to a wide range of materials with proper settings.

-

Color Palette:

- Traditional: Limited by available thread colors and blending techniques.

- Digitized: Extensive color options with precise color matching.

-

Design Reproduction:

- Traditional: Challenging to recreate exact designs.

- Digitized: Designs can be stored, modified, and reproduced with ease.

-

Scalability:

- Traditional: Difficult to scale designs without redrawing.

- Digitized: Designs can be easily resized while maintaining quality.

While traditional embroidery maintains its charm and artisanal value, digitized embroidery has revolutionized the industry. It's worth noting that MaggieFrame's magnetic embroidery hoops enhance the digitized embroidery process by providing superior fabric stability, which is crucial for achieving precise results across various materials and design complexities.

2.3 Role of Technology in Modern Embroidery

Technology has become the backbone of modern embroidery, transforming every aspect of the craft from design conception to final production. Here's how technology is shaping the embroidery landscape:

-

Advanced Design Software:

Cutting-edge digitizing software offers features like auto-digitizing, stitch simulation, and 3D visualization. These tools allow digitizers to refine designs with unprecedented precision before they reach the machine. -

Machine Integration:

Modern embroidery machines are equipped with computer-controlled systems that seamlessly interpret digitized designs. This integration minimizes human error and enhances consistency across production runs. -

Color Management Systems:

Digital technology enables accurate color matching and blending, allowing for more vibrant and complex designs. Software can suggest optimal thread colors and simulate their appearance on different fabrics. -

Stitch Optimization Algorithms:

Intelligent algorithms within digitizing software automatically optimize stitch patterns for different fabrics and design elements, improving efficiency and quality. -

Cloud-Based Collaboration:

Cloud technology facilitates real-time collaboration between designers, clients, and production teams, streamlining the approval process and enhancing communication. -

Machine Learning and AI:

Emerging AI technologies are revolutionizing embroidery digitizing, offering features like automatic design suggestions, pattern recognition, and predictive maintenance for embroidery machines. -

Digital Asset Management:

Large-scale embroidery operations benefit from digital systems that manage vast libraries of designs, ensuring easy access and version control. -

Quality Control Technologies:

Digital imaging and analysis tools can inspect finished embroidery, comparing it to the original design to ensure quality standards are met. -

Sustainable Practices:

Technology aids in optimizing resource use, reducing waste by calculating precise thread requirements and minimizing errors that could lead to material waste. -

Customization at Scale:

Digital processes allow for mass customization, enabling businesses to offer personalized embroidery efficiently, even for large orders. -

Augmented Reality (AR) Previews:

AR technology allows customers to visualize embroidered designs on products before ordering, enhancing the customer experience and reducing returns. -

IoT in Embroidery Production:

Internet of Things (IoT) devices monitor machine performance, track production metrics, and alert operators to potential issues, increasing overall efficiency.

In this technologically advanced landscape, MaggieFrame's magnetic embroidery hoops play a crucial role. Their innovative design complements modern embroidery machines, providing enhanced stability and precision. This synergy between software, hardware, and accessories like MaggieFrame hoops is driving the embroidery industry towards new heights of efficiency and creativity.

By leveraging these technological advancements, embroidery has become more efficient, accurate, and versatile. It has opened up new creative possibilities while simultaneously improving production speed and consistency. As technology continues to evolve, we can expect even more innovations in the field of embroidery, further enhancing its capabilities and applications across various industries.

3. Key Benefits of Embroidery Digitizing for Businesses

3.1 Enhanced Precision and Consistency

In the world of embroidery, precision and consistency are paramount. Embroidery digitizing has revolutionized the industry by offering unparalleled accuracy in design reproduction. This technology allows businesses to achieve a level of detail and uniformity that was once unimaginable with traditional embroidery methods.

3.1.1 Pixel-Perfect Design Reproduction

Embroidery digitizing software translates designs into stitch-by-stitch instructions for embroidery machines. This process ensures that even the most intricate details of a logo or design are captured and reproduced with stunning accuracy. For businesses, this means that their brand identity can be faithfully represented on various products, from corporate uniforms to promotional items.

3.1.2 Consistent Results Across Multiple Items

One of the most significant advantages of digitized embroidery is the ability to replicate designs with perfect consistency across multiple items. Whether you're producing a dozen or a thousand pieces, each embroidered product will be virtually identical. This consistency is crucial for maintaining brand integrity and professional appearance, especially for businesses that rely on uniformed staff or branded merchandise.

3.1.3 Minimizing Human Error

By automating the embroidery process through digitization, businesses can significantly reduce the risk of human error. Traditional hand embroidery, while beautiful, is subject to variations and mistakes. Digitized embroidery eliminates these inconsistencies, ensuring that each stitch is placed exactly where it should be, time after time.

3.1.4 Precision in Complex Designs

Embroidery digitizing excels in handling complex designs that would be challenging or impossible to recreate consistently by hand. Intricate patterns, gradients, and small text can be reproduced with remarkable clarity and precision. This capability opens up new possibilities for businesses to create more sophisticated and eye-catching embroidered products.

3.1.5 Maintaining Quality Across Different Fabrics

Digitizing allows for adjustments to be made based on the specific fabric being embroidered. The software can compensate for different materials' stretch, thickness, and texture, ensuring that the final embroidered design looks consistent regardless of the substrate. This versatility is particularly valuable for businesses that offer a wide range of embroidered products.

By leveraging the enhanced precision and consistency offered by embroidery digitizing, businesses can elevate their brand presentation, improve product quality, and maintain a professional image across all their embroidered items. The ability to reproduce complex designs with pinpoint accuracy not only saves time and resources but also allows for greater creativity and brand expression.

For businesses looking to maximize the benefits of precision and consistency in their embroidery projects, MaggieFrame's magnetic embroidery hoops provide an excellent complement to digitized designs. These innovative hoops offer superior fabric stability during the embroidery process, further enhancing the accuracy of stitch placement and ensuring that the digitized design is executed flawlessly on the fabric. The combination of precise digitizing and MaggieFrame's stable hooping system results in embroidery that truly stands out in quality and consistency.

3.2 Increased Efficiency and Productivity

Embroidery digitizing has revolutionized the embroidery industry, offering businesses a significant boost in efficiency and productivity. This technological advancement has transformed the way embroidery is conceptualized, designed, and executed, leading to streamlined processes and faster turnaround times.

3.2.1 Streamlined Design Process

The digitizing process allows for quick and easy design creation and modification. Designers can work directly on digital platforms, making alterations and refinements in real-time. This streamlined approach significantly reduces the time spent on design development, allowing businesses to respond swiftly to client requests and market trends.

3.2.2 Rapid Prototyping and Sampling

With embroidery digitizing, businesses can quickly create digital prototypes of designs. These virtual samples can be reviewed and adjusted without the need for physical production, saving both time and materials. This rapid prototyping capability enables faster decision-making and more efficient client approvals.

3.2.3 Automated Stitching Process

Once a design is digitized, it can be instantly transferred to embroidery machines. These machines can then execute the design with minimal human intervention, working tirelessly and consistently. This automation drastically reduces production time, especially for large orders or complex designs that would be time-consuming to embroider manually.

3.2.4 Multi-Head Embroidery Capabilities

Digitized designs can be simultaneously executed on multi-head embroidery machines. This parallel production capability allows businesses to complete large orders in a fraction of the time it would take with traditional methods. For instance, a design that might take an hour to embroider on a single item can be replicated on dozens of items in the same timeframe.

3.2.5 Reduced Setup Time

Embroidery digitizing eliminates the need for manual pattern setup for each new design. Once a design is digitized, it can be quickly loaded onto any compatible embroidery machine, significantly reducing setup time between projects. This efficiency is particularly beneficial for businesses that handle a variety of designs or frequent order changes.

3.2.6 Enhanced Quality Control

Digitized embroidery allows for precise control over stitch types, densities, and directions. This level of control not only improves the quality of the final product but also reduces the likelihood of errors and the need for rework. The result is a more efficient production process with fewer interruptions and less waste.

3.2.7 Integration with Other Systems

Embroidery digitizing software can often integrate with other business systems, such as order management and inventory control. This integration streamlines the entire production process, from order placement to final delivery, enhancing overall operational efficiency.

By embracing embroidery digitizing, businesses can significantly increase their output without compromising on quality. The technology allows for faster turnaround times, reduced labor costs, and the ability to handle larger volumes of work. This increased efficiency and productivity translate directly into improved profitability and competitiveness in the market.

It's worth noting that to fully leverage the efficiency gains of embroidery digitizing, businesses should also consider complementary tools that enhance the embroidery process. For instance, MaggieFrame's magnetic embroidery hoops offer quick and easy fabric positioning, reducing the time spent on hooping and minimizing human error. These hoops are designed to work seamlessly with a wide range of industrial embroidery machines, further streamlining the production process and maximizing the benefits of digitized embroidery.

3.3 Cost-Effectiveness in Large-Scale Production

Embroidery digitizing has revolutionized the economics of large-scale embroidery production, offering businesses significant cost advantages that were previously unattainable. This technology has transformed the embroidery landscape, making it possible to produce high-quality, custom embroidered items in large quantities without a proportional increase in costs.

3.3.1 Reduced Labor Costs

One of the most significant cost benefits of embroidery digitizing in large-scale production is the dramatic reduction in labor costs. Once a design is digitized, it can be executed by automated embroidery machines with minimal human intervention. This automation eliminates the need for skilled embroiderers to manually create each piece, significantly reducing labor hours and associated costs.

3.3.2 Minimized Material Waste

Digitized embroidery allows for precise calculation and control of thread usage. The software can optimize stitch patterns to minimize thread consumption without compromising on design quality. This precision leads to reduced material waste, which can result in substantial savings, especially in large production runs where even small per-item savings can add up to significant amounts.

3.3.3 Economies of Scale

As production volume increases, the initial cost of digitizing a design is spread across more units, effectively lowering the per-item cost. This scalability makes digitized embroidery particularly cost-effective for large orders, allowing businesses to offer competitive pricing while maintaining healthy profit margins.

3.3.4 Faster Turnaround Times

The speed and efficiency of digitized embroidery translate directly into cost savings. Faster production means more efficient use of equipment and facilities, allowing businesses to take on more orders and increase their revenue without a proportional increase in overhead costs.

3.3.5 Consistent Quality Reduces Rework

The precision and consistency of digitized embroidery significantly reduce the likelihood of errors and the need for rework. This consistency ensures that fewer items are rejected due to quality issues, minimizing waste and the costs associated with correcting mistakes or reproducing items.

3.3.6 Versatility in Production

Digitized designs can be easily scaled and modified to fit different products without incurring additional design costs. This versatility allows businesses to efficiently produce a wide range of items using the same basic design, maximizing the return on their initial digitizing investment.

3.3.7 Lower Training and Skill Requirements

While skilled digitizers are still valuable, the operation of embroidery machines with digitized designs requires less specialized training. This reduced skill requirement can lead to lower training costs and more flexibility in staffing, further contributing to cost-effectiveness in large-scale production.

To fully capitalize on the cost-effectiveness of digitized embroidery in large-scale production, businesses should consider complementary tools that enhance efficiency and quality. For instance, MaggieFrame's magnetic embroidery hoops offer a solution that significantly reduces hooping time and improves fabric stability during the embroidery process. These hoops are designed for quick and easy fabric positioning, which is particularly beneficial in high-volume production environments. By minimizing fabric distortion and ensuring consistent tension, MaggieFrame hoops help maintain the quality of embroidered designs while speeding up the production process, further enhancing the cost-effectiveness of large-scale embroidery operations.

In conclusion, embroidery digitizing has transformed large-scale production by offering substantial cost savings through reduced labor, minimized waste, and increased efficiency. This technology enables businesses to produce high-quality embroidered items at scale, meeting market demands while maintaining competitive pricing and healthy profit margins.

3.4 Versatility in Design and Application

Embroidery digitizing has opened up a world of possibilities in design and application, offering businesses unprecedented versatility in their embroidery offerings. This technological advancement has expanded the creative horizons of embroidery, allowing for complex designs, diverse applications, and quick adaptations to market trends.

3.4.1 Complex Design Capabilities

Digitizing enables the creation of intricate and detailed designs that would be challenging or impossible to achieve through traditional embroidery methods. Businesses can now offer photorealistic embroidery, complex gradients, and fine detail work, expanding their design repertoire and attracting a wider range of clients.

3.4.2 Easy Design Modifications

With digitized designs, making alterations becomes a simple and quick process. Colors can be changed, elements can be added or removed, and sizes can be adjusted with just a few clicks. This flexibility allows businesses to quickly respond to client requests or market trends without starting the design process from scratch.

3.4.3 Multi-Material Compatibility

Digitized embroidery can be optimized for a wide range of materials, from delicate silks to sturdy denims. The software allows for adjustments in stitch type, density, and direction to suit different fabrics, ensuring high-quality results across various products. This versatility enables businesses to expand their product lines and cater to diverse market segments.

3.4.4 Scalability of Designs

Digitized designs can be easily scaled up or down without losing quality. A logo that looks great on a small pocket can be quickly resized for a large jacket back, maintaining its proportions and detail. This scalability allows businesses to use a single design across multiple product types and sizes, maximizing the utility of each digitized design.

3.4.5 Integration with Other Decoration Techniques

Embroidery digitizing software often allows for integration with other decoration techniques such as appliqué, sequins, or even laser cutting. This integration enables businesses to create unique, multi-technique designs that stand out in the market and command premium pricing.

3.4.6 Customization and Personalization

The ease of modifying digitized designs makes customization and personalization highly efficient. Businesses can offer personalized products, such as monogrammed items or team uniforms with individual names and numbers, without significantly increasing production time or costs.

3.4.7 Rapid Prototyping and Sampling

Digitizing allows for quick creation of virtual samples, enabling businesses to present design concepts to clients without the need for physical production. This capability speeds up the approval process and allows for more design iterations, resulting in better final products and increased client satisfaction.

3.4.8 Adaptation to New Products

As new products enter the market, digitized designs can be quickly adapted to fit these new applications. Whether it's a newly developed fabric or an innovative product shape, the flexibility of digitized embroidery allows businesses to stay at the forefront of market trends.

To fully leverage the versatility offered by embroidery digitizing, businesses can benefit from complementary tools that enhance their capabilities. For instance, MaggieFrame's magnetic embroidery hoops offer superior fabric stability and ease of use across a wide range of materials and product types. These hoops are particularly beneficial when working with challenging fabrics or unique product shapes, as they provide consistent tension and minimize fabric distortion. The universal compatibility of MaggieFrame hoops with various industrial embroidery machines further enhances a business's ability to adapt and expand its embroidery offerings.

In conclusion, the versatility in design and application offered by embroidery digitizing empowers businesses to expand their creative boundaries, respond quickly to market demands, and offer a wider range of high-quality embroidered products. This flexibility not only enhances customer satisfaction but also opens up new revenue streams and market opportunities for embroidery businesses.

3.5 Improved Quality Control

Embroidery digitizing has significantly enhanced the ability of businesses to maintain and improve the quality of their embroidered products. This technology provides unprecedented control over various aspects of the embroidery process, resulting in consistently high-quality outputs and reduced errors.

3.5.1 Precise Stitch Placement

Digitized embroidery allows for exact placement of each stitch, ensuring that designs are reproduced with pinpoint accuracy. This level of precision is particularly crucial for intricate designs, logos, and text, where even small deviations can be noticeable. The ability to control stitch placement down to fractions of a millimeter results in cleaner, more professional-looking embroidery.

3.5.2 Consistent Stitch Density

Embroidery digitizing software enables precise control over stitch density. This control is essential for achieving the right balance between design clarity and fabric integrity. Consistent stitch density across different production runs ensures that embroidered items maintain a uniform appearance, which is crucial for brand consistency and customer satisfaction.

3.5.3 Color Accuracy and Consistency

Digitized designs include specific color information that can be consistently reproduced across multiple embroidery machines and production runs. This color consistency is vital for maintaining brand identity and ensuring that all embroidered items match perfectly, regardless of when or where they were produced.

3.5.4 Automated Quality Checks

Many embroidery digitizing systems include automated quality check features. These can detect potential issues such as excessive stitch density, long jump stitches, or areas prone to thread breaks before production begins. By identifying and addressing these issues in the digital stage, businesses can prevent quality problems in the final product.

3.5.5 Repeatable Results

Once a design is digitized and optimized, it can be reproduced with exact precision every time. This repeatability eliminates variations that can occur with manual embroidery methods, ensuring consistent quality across large production runs and over extended periods.

3.5.6 Fabric-Specific Optimizations

Embroidery digitizing software allows for adjustments based on specific fabric types. Parameters such as pull compensation, underlay stitches, and stitch direction can be fine-tuned for different materials, ensuring optimal results on various fabrics without compromising design integrity.

3.5.7 Real-Time Monitoring and Adjustments

Advanced embroidery machines paired with digitized designs often offer real-time monitoring capabilities. This feature allows operators to detect and address quality issues as they occur, minimizing waste and ensuring that the entire production run meets quality standards.

3.5.8 Detailed Production Records

Digitizing systems can maintain detailed records of each design and production run. These records are invaluable for quality control, allowing businesses to track changes, replicate successful runs, and quickly identify the source of any quality issues that may arise.

To further enhance quality control in embroidery production, businesses can complement their digitizing technology with high-quality embroidery tools. MaggieFrame's magnetic embroidery hoops, for instance, play a crucial role in maintaining fabric stability during the embroidery process. These hoops provide consistent tension across the fabric, reducing the risk of puckering, misalignment, and other quality issues that can occur due to fabric movement. The precise and stable hooping offered by MaggieFrame products ensures that the accuracy of digitized designs is faithfully translated to the final embroidered product.

Moreover, MaggieFrame hoops are designed to be compatible with a wide range of industrial embroidery machines, allowing businesses to maintain consistent quality standards across different equipment setups. This compatibility is particularly beneficial for businesses operating multiple production lines or outsourcing part of their production.

In conclusion, improved quality control through embroidery digitizing enables businesses to produce higher quality embroidered products with greater consistency. This enhanced quality control not only leads to increased customer satisfaction and brand reputation but also reduces waste and rework, contributing to overall operational efficiency and profitability.

4. Applications of Embroidery Digitizing

4.1 Corporate Branding and Uniforms

In today's competitive business landscape, corporate branding plays a crucial role in establishing a strong company identity. Embroidery digitizing has revolutionized the way businesses approach their branding strategies, particularly when it comes to corporate uniforms and promotional items. This section explores how embroidery digitizing enhances corporate branding efforts and elevates the professional appearance of uniforms.

4.1.1 Consistent Brand Representation

Embroidery digitizing ensures that company logos and insignias are reproduced with impeccable precision across all corporate uniforms. This consistency is vital for maintaining a cohesive brand image, whether it's on the polo shirts of a retail team or the jackets of a corporate executive board.

4.1.2 Customization for Different Departments

With digitized embroidery, companies can easily customize uniforms for different departments or roles within the organization. For example, a hotel chain might use different color schemes or design elements for housekeeping, front desk, and management staff, all while maintaining the core brand identity.

4.1.3 Scalability for Growing Businesses

As businesses grow and expand, embroidery digitizing allows for seamless scaling of uniform production. The digitized designs can be quickly and accurately reproduced on new uniforms, ensuring that new employees or new branches maintain the same professional appearance.

4.1.4 Enhanced Durability and Professionalism

Digitized embroidery offers superior durability compared to printed logos, ensuring that the brand representation on uniforms remains crisp and professional even after multiple washes. This longevity is particularly important for industries where uniforms undergo frequent use and cleaning.

4.1.5 Versatility in Fabric and Placement

Embroidery digitizing allows for the application of logos and designs on a wide variety of fabrics and garment types. From lightweight polo shirts to heavy-duty work jackets, the digitized designs can be optimized for different materials, ensuring quality results across the entire range of corporate attire.

4.1.6 Cost-Effective Branding Solution

While the initial setup for embroidery digitizing may require an investment, it proves to be a cost-effective solution in the long run, especially for larger organizations. The ability to produce high-quality, consistent branding on uniforms in-house or through a dedicated supplier can significantly reduce long-term costs associated with corporate branding.

4.1.7 Integration with Employee Recognition Programs

Digitized embroidery enables easy customization for employee recognition programs. Companies can add names, achievements, or years of service to uniforms, fostering a sense of pride and belonging among employees while maintaining the overall brand aesthetic.

To maximize the benefits of embroidery digitizing for corporate branding and uniforms, businesses should consider using high-quality embroidery tools. MaggieFrame's magnetic embroidery hoops, for instance, offer superior stability during the embroidery process, ensuring that even the most intricate logo designs are reproduced with precision. The universal compatibility of MaggieFrame hoops with various industrial embroidery machines makes them an ideal choice for businesses looking to maintain consistency across different production setups or locations.

By leveraging embroidery digitizing for corporate branding and uniforms, businesses can create a strong, professional image that resonates with both employees and customers. The precision, versatility, and durability offered by this technology make it an invaluable tool in the modern corporate branding toolkit.

4.2 Promotional Products and Merchandise

Embroidery digitizing has transformed the landscape of promotional products and merchandise, offering businesses unprecedented opportunities to create unique, high-quality items that leave a lasting impression. This section explores how embroidery digitizing enhances the creation and production of promotional products, elevating brand visibility and customer engagement.

4.2.1 Versatility in Product Range

Embroidery digitizing allows for the application of logos and designs on a wide array of promotional products:

- Apparel: Caps, t-shirts, jackets, and bags

- Accessories: Towels, umbrellas, and laptop sleeves

- Office items: Mousepads, notebook covers, and desk organizers

This versatility enables businesses to create a cohesive brand presence across various product categories, catering to different customer preferences and use cases.

4.2.2 Precision in Detail Reproduction

With embroidery digitizing, even the most intricate logo designs can be reproduced with exceptional accuracy on promotional items. This precision ensures that brand elements, no matter how complex, are faithfully represented, enhancing the perceived value of the promotional products.

4.2.3 Customization and Personalization

Digitized embroidery facilitates easy customization of promotional products:

- Event-specific merchandise with dates and locations

- Personalized items with individual names or messages

- Limited edition runs with unique design elements

This flexibility allows businesses to create targeted promotional campaigns that resonate more deeply with their audience.

4.2.4 Durability for Long-lasting Brand Exposure

Embroidered promotional products offer superior durability compared to printed alternatives. The longevity of embroidered items ensures that the brand remains visible and intact for an extended period, maximizing the return on investment for promotional campaigns.

4.2.5 Premium Perception and Brand Positioning

The high-quality finish of embroidered promotional products contributes to a premium brand perception. Businesses can leverage this to position themselves as quality-focused entities, distinguishing their merchandise from competitors who may opt for less durable printing methods.

4.2.6 Consistency Across Product Lines

Embroidery digitizing ensures consistency in logo reproduction across different product lines. Whether it's a small logo on a pen or a large design on a jacket back, the digitized file can be scaled and adjusted while maintaining the integrity of the design.

4.2.7 Cost-Effective Production for Bulk Orders

While the initial setup for embroidery digitizing may involve some costs, it becomes highly cost-effective for bulk production of promotional items. Once a design is digitized, it can be reproduced countless times without additional design fees, making it ideal for large-scale promotional campaigns.

4.2.8 Enhanced Creativity in Design

Digitized embroidery opens up new creative possibilities for promotional product design:

- Multi-color designs with seamless color transitions

- Textured effects that add depth to logos

- Combination of embroidery with other decoration techniques

This creativity allows businesses to create truly unique promotional items that stand out in a crowded marketplace.

To maximize the quality and efficiency of embroidered promotional products, businesses should consider using advanced embroidery tools. MaggieFrame's magnetic embroidery hoops, for instance, offer superior fabric stability during the embroidery process. This stability is crucial when working with various materials used in promotional products, from soft fabrics to more rigid items. The universal compatibility of MaggieFrame hoops with different industrial embroidery machines ensures consistent quality across large production runs, which is essential for promotional merchandise campaigns.

By leveraging embroidery digitizing for promotional products and merchandise, businesses can create high-quality, lasting promotional items that effectively communicate their brand values and message. The combination of durability, precision, and versatility makes digitized embroidery an invaluable tool in modern marketing and brand promotion strategies.

4.3 Fashion and Retail Industry

Embroidery digitizing has revolutionized the fashion and retail industry, offering designers and manufacturers unprecedented creative freedom and production efficiency. This section explores how digitized embroidery is reshaping fashion trends, enhancing product quality, and streamlining the production process in the fast-paced world of retail.

4.3.1 Haute Couture and High-End Fashion

In the realm of haute couture, embroidery digitizing has opened up new avenues for intricate and complex designs:

- Creation of elaborate, one-of-a-kind embroidered patterns

- Precision in reproducing delicate, artistic embroidery on luxury garments

- Ability to experiment with unconventional materials and textures

Designers can now push the boundaries of creativity, translating their most ambitious visions into wearable art with unparalleled accuracy.

4.3.2 Fast Fashion and Mass Production

For fast fashion retailers, embroidery digitizing offers significant advantages:

- Rapid turnaround from design concept to production

- Consistent quality across large production runs

- Easy adaptation of designs for different garment styles and sizes

This technology allows retailers to quickly respond to emerging trends and consumer demands, bringing embroidered fashion to the mass market efficiently.

4.3.3 Customization and Personalization Trends

Embroidery digitizing caters to the growing demand for personalized fashion:

- On-demand customization of garments with names, initials, or personal designs

- Creation of limited edition or exclusive embroidered pieces

- Integration with online platforms for customer-designed embroidery

This level of customization enhances customer engagement and satisfaction, offering a unique shopping experience.

4.3.4 Sustainable Fashion Practices

Digitized embroidery contributes to sustainable fashion practices:

- Reduction in material waste through precise design execution

- Durability of embroidered designs, extending garment lifespan

- Potential for using eco-friendly threads and fabrics in embroidery

These aspects align with the growing consumer demand for sustainable and ethical fashion choices.

4.3.5 Innovative Textile Applications

Embroidery digitizing is not limited to traditional fabrics:

- Application on technical textiles for sportswear and activewear

- Integration with smart fabrics and wearable technology

- Embellishment of accessories like shoes, bags, and belts

This versatility allows for innovative product development across various retail categories.

4.3.6 Brand Identity and Logos in Fashion

Fashion brands leverage embroidery digitizing for consistent brand representation:

- Precise reproduction of brand logos on garments and accessories

- Creation of signature embroidered patterns for brand recognition

- Ability to adapt brand elements across different product lines

This consistency in branding helps build strong brand identity and recognition in the competitive fashion market.

4.3.7 Collaboration with Artists and Designers

Embroidery digitizing facilitates collaborations between fashion brands and artists:

- Accurate translation of artistic designs into embroidered form

- Limited edition collections featuring unique embroidered artwork

- Cross-disciplinary projects merging fashion with other art forms

These collaborations bring fresh perspectives and unique offerings to the fashion industry.

4.3.8 Enhanced Quality Control

In retail production, embroidery digitizing improves quality control:

- Consistent stitch quality across large production runs

- Easier detection and correction of design flaws before mass production

- Ability to maintain design integrity across different fabric types

This level of control ensures that the final products meet high-quality standards, crucial for customer satisfaction and brand reputation.

To maximize the benefits of embroidery digitizing in fashion and retail, manufacturers can enhance their production capabilities with advanced embroidery tools. MaggieFrame's magnetic embroidery hoops, for instance, offer superior stability during the embroidery process, which is crucial when working with delicate fabrics or creating intricate designs common in fashion. The universal compatibility of MaggieFrame hoops with various industrial embroidery machines ensures consistent quality across different production lines or outsourced manufacturing, a key consideration for fashion brands maintaining quality across global supply chains.

Embroidery digitizing has become an integral part of the fashion and retail industry, enabling designers and manufacturers to create unique, high-quality products efficiently. From haute couture to fast fashion, this technology continues to drive innovation, sustainability, and personalization in the ever-evolving world of fashion retail.

4.4 Personalized Gifts and Custom Apparel

Embroidery digitizing has revolutionized the personalized gifts and custom apparel market, offering unprecedented opportunities for creating unique, high-quality items. This section explores how digitized embroidery enhances the creation of personalized products, catering to the growing demand for customized gifts and apparel.

4.4.1 Customization Options

Embroidery digitizing provides a wide range of customization options:

- Names and initials on clothing, bags, and accessories

- Commemorative dates and messages on special occasion items

- Custom logos and designs for clubs, teams, or events

- Family crests or personal symbols on heirloom-quality pieces

These options allow for deeply personal and meaningful customization, making each item unique to the recipient.

4.4.2 Versatility in Gift Items

The applications of digitized embroidery in personalized gifts are extensive:

- Apparel: Shirts, jackets, hats, and robes

- Home decor: Pillows, blankets, and towels

- Accessories: Bags, wallets, and phone cases

- Baby items: Bibs, blankets, and stuffed animals

This versatility ensures that there's a personalized embroidered gift option for every occasion and recipient.

4.4.3 Quality and Durability

Digitized embroidery offers superior quality and durability for personalized items:

- Precise and consistent stitch quality

- Long-lasting designs that withstand washing and wear

- Professional finish that enhances the perceived value of the gift

These qualities make embroidered gifts cherished keepsakes that last for years.

4.4.4 Rapid Turnaround for Custom Orders

Embroidery digitizing streamlines the production process for custom orders:

- Quick transition from design approval to production

- Efficient execution of individual customizations

- Ability to handle rush orders for time-sensitive occasions

This efficiency is crucial in meeting customer expectations for personalized products.

4.4.5 Scalability for Business Growth

For businesses offering personalized gifts and custom apparel, embroidery digitizing provides scalability:

- Easy replication of popular designs

- Consistent quality across multiple orders

- Ability to handle large volume orders without compromising on personalization

This scalability allows businesses to grow while maintaining the quality and uniqueness of their offerings.

4.4.6 Integration with E-commerce Platforms

Digitized embroidery integrates seamlessly with online customization tools:

- Interactive design interfaces for customers to create their own designs

- Preview capabilities for customers to visualize the final product

- Streamlined order processing from customization to production

This integration enhances the online shopping experience for personalized products.

4.4.7 Corporate Gifting Solutions

Embroidery digitizing offers sophisticated solutions for corporate gifting:

- Consistent branding across a range of gift items

- Ability to personalize items for individual employees or clients

- High-quality, professional appearance suitable for corporate environments

These features make embroidered items excellent choices for corporate recognition programs and client appreciation gifts.

4.4.8 Seasonal and Themed Collections

Digitized embroidery allows for quick development of seasonal and themed collections:

- Holiday-specific designs and messages

- Sports team and fan merchandise

- Cultural and regional motifs for targeted markets

This flexibility enables businesses to respond quickly to market trends and seasonal demands.

To enhance the quality and efficiency of personalized embroidery production, businesses can benefit from using advanced embroidery tools. MaggieFrame's magnetic embroidery hoops, for instance, offer superior fabric stability during the embroidery process. This stability is crucial when working with various materials and creating intricate personalized designs. The universal compatibility of MaggieFrame hoops with different industrial embroidery machines ensures consistent quality across various product types, which is essential for businesses offering a wide range of personalized items.

Embroidery digitizing has transformed the personalized gifts and custom apparel industry, offering a perfect blend of quality, efficiency, and customization. By leveraging this technology, businesses can create unique, high-quality personalized products that resonate with customers and stand out in the competitive gift market.

4.5 Industrial and Specialized Uses

Embroidery digitizing has found its way into various industrial and specialized applications, extending far beyond traditional textile and fashion industries. This section explores how digitized embroidery is being utilized in diverse sectors, showcasing its versatility and importance in specialized fields.

4.5.1 Automotive Industry

In the automotive sector, embroidery digitizing plays a crucial role:

- Custom embroidered logos on car seats and headrests

- Personalized embroidery for luxury vehicle interiors

- Durable labels and tags for car components

The precision and durability of digitized embroidery make it ideal for the demanding standards of automotive manufacturing.

4.5.2 Aerospace and Aviation

The aerospace industry utilizes embroidery digitizing for:

- Safety instruction labels on aircraft seats and equipment

- Personalized name tags on pilot and crew uniforms

- Embroidered patches for flight jackets and uniforms

The high-quality, long-lasting nature of embroidered designs is crucial in this safety-critical industry.

4.5.3 Military and Defense

Embroidery digitizing is extensively used in military applications:

- Rank insignias and unit patches on uniforms

- Personalized name tags and blood type indicators

- Camouflage pattern enhancements on specialized gear

The ability to produce consistent, regulation-compliant designs is essential in military contexts.

4.5.4 Medical and Healthcare

In the healthcare sector, embroidery digitizing serves various purposes:

- Clear identification on medical staff uniforms

- Customized patient gowns and linens for hospitals

- Embroidered labels on medical equipment and supplies

The use of embroidery ensures durable, hygienic labeling that can withstand frequent washing and sterilization.

4.5.5 Sports and Athletics

The sports industry heavily relies on embroidery digitizing for:

- Team logos and player names on uniforms

- Customized sports equipment like

5. The Embroidery Digitizing Process

5.1 Converting Artwork to Digital Format

The first step in the embroidery digitizing process is converting artwork into a digital format suitable for embroidery machines. This crucial stage sets the foundation for the entire embroidery project, ensuring that the final product accurately represents the original design.

5.1.1 Selecting the Right File Format

When converting artwork, it's essential to choose the appropriate file format:

- Vector files (e.g., .ai, .eps, .svg) are ideal for logos and text-based designs.

- High-resolution raster images (e.g., .png, .jpg) work well for complex, photorealistic designs.

- Native embroidery files (.dst, .emb, .pes) are perfect for direct machine use.

5.1.2 Cleaning and Simplifying the Artwork

Before digitization, the artwork often needs to be cleaned up and simplified:

- Remove unnecessary details that may not translate well to embroidery.

- Smooth out jagged edges and simplify complex shapes.

- Adjust color gradients to work within the limitations of thread colors.

5.1.3 Scaling and Positioning

Proper scaling and positioning are crucial for accurate embroidery:

- Resize the artwork to match the intended embroidery dimensions.

- Consider the placement on the garment or item to be embroidered.

- Adjust the design elements to ensure they will be visible and legible when embroidered.

5.1.4 Color Separation

Separating colors in the digital artwork is essential for creating an efficient embroidery process:

- Identify distinct color areas in the design.

- Create separate layers or elements for each color to be embroidered.

- Consider color blending techniques for gradients or shading effects.

By meticulously converting artwork to a digital format, embroiderers lay the groundwork for a successful digitization process. This attention to detail ensures that the subsequent steps in the embroidery digitizing process can be executed with precision and efficiency.

To enhance the accuracy of design placement during this crucial stage, many professional embroiderers rely on MaggieFrame's magnetic embroidery hoops. These innovative hoops provide superior fabric stability, which is particularly beneficial when working with complex designs that require precise positioning. The universal compatibility of MaggieFrame hoops with various industrial embroidery machines ensures consistent results across different setups, making them an invaluable tool in the digitizing process.

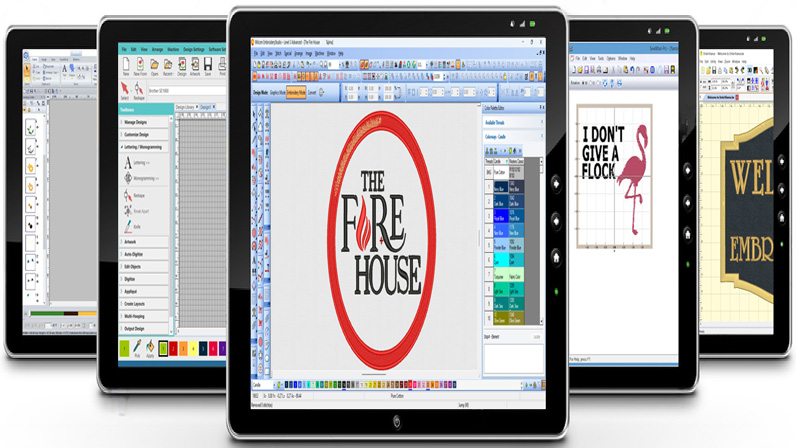

5.2 Software Tools for Digitizing

Embroidery digitizing software is the backbone of the modern embroidery process, transforming digital artwork into stitch-ready files for embroidery machines. These powerful tools offer a range of features that enable digitizers to create intricate, high-quality embroidery designs with precision and efficiency.

5.2.1 Popular Embroidery Digitizing Software

Several software options dominate the market, each with its unique strengths:

- Wilcom Embroidery Studio: Known for its comprehensive features and professional-grade output.

- Hatch Embroidery: User-friendly interface with powerful digitizing capabilities.

- Embrilliance: Offers a range of products for different skill levels and needs.

- Pulse Embroidery: Robust software with advanced digitizing and editing tools.

- Sierra Embroidery Office: Versatile software with a focus on productivity.

5.2.2 Key Features of Digitizing Software

Modern embroidery digitizing software typically includes:

- Auto-digitizing tools: Automatically convert vector or raster images into stitch files.

- Manual digitizing tools: Allow for precise control over stitch placement and types.

- Stitch editing: Fine-tune individual stitches or entire sections of a design.

- Thread color management: Match thread colors to design specifications.

- 3D visualization: Preview how designs will look when embroidered.

- Machine format compatibility: Export designs in various file formats for different embroidery machines.

5.2.3 Advanced Software Capabilities

High-end digitizing software often offers advanced features such as:

- Fabric assistance: Automatically adjust stitch settings based on fabric type.

- Lettering tools: Create and manipulate text with embroidery-specific fonts.

- Appliqué digitizing: Design and create appliqué patterns within the software.

- Photorealistic rendering: Generate lifelike previews of embroidered designs.

- Custom stitch creation: Develop unique stitch types for special effects.

5.2.4 Integration with Embroidery Equipment

Effective digitizing software seamlessly integrates with embroidery machines:

- Direct machine connection: Send designs directly to compatible embroidery machines.

- Multi-head support: Manage designs for multi-head embroidery machines.

- Production scheduling: Plan and organize embroidery production runs.

While the choice of software is crucial, it's equally important to pair it with high-quality embroidery equipment. MaggieFrame's magnetic embroidery hoops, for instance, complement digitizing software by providing superior fabric stability during the embroidery process. This synergy between software and hardware ensures that the precision of digitized designs is faithfully reproduced in the final embroidered product.

By leveraging these sophisticated software tools and complementary hardware like MaggieFrame hoops, embroidery professionals can push the boundaries of design complexity and quality, meeting the ever-increasing demands of the modern embroidery market.

5.3 Steps in the Digitizing Process

The embroidery digitizing process is a meticulous journey that transforms artwork into a stitch-ready file. Each step is crucial in ensuring the final embroidered product faithfully represents the original design while optimizing for the embroidery process. Let's explore the key steps involved:

5.3.1 Analyzing the Artwork

Before beginning the digitizing process, a thorough analysis of the artwork is essential:

- Evaluate design complexity and identify potential challenges.

- Consider the intended fabric and final product size.

- Plan the sequence of stitches and color changes for optimal efficiency.

5.3.2 Setting Parameters

Proper parameter setting is crucial for achieving the desired results:

- Define the embroidery area dimensions.

- Set the appropriate stitch density for different design elements.

- Adjust pull compensation to account for fabric distortion.

- Determine underlay stitches to stabilize the fabric.

5.3.3 Digitizing the Design

The actual digitizing process involves several sub-steps:

- Outline Creation: Trace the main elements of the design.

- Stitch Type Selection: Choose appropriate stitch types for each design element (e.g., satin stitch for borders, fill stitch for larger areas).

- Stitch Direction: Set the direction of stitches to enhance the design's texture and appearance.

- Color Sequencing: Organize the stitching order to minimize color changes and maximize efficiency.

5.3.4 Adding Texture and Depth

Enhance the design's visual appeal and realism:

- Incorporate specialized stitch effects like 3D puff or textured fills.

- Use varying stitch lengths and densities to create shading and dimension.

- Blend colors to achieve gradient effects where appropriate.

5.3.5 Optimizing for Production

Fine-tune the design for efficient embroidery:

- Minimize jump stitches to reduce production time and trimming.

- Optimize entry and exit points for smooth transitions between elements.

- Adjust stitch count to balance quality with production speed.

5.3.6 Testing and Refinement

Before finalizing the design, thorough testing is crucial:

- Generate a stitch-out on the intended fabric or a similar material.

- Evaluate the embroidery quality, paying attention to detail and overall appearance.

- Make necessary adjustments based on the test results, such as tweaking densities or pull compensation.

5.3.7 File Preparation and Export

The final step involves preparing the digitized file for production:

- Review and double-check all design elements and settings.

- Generate the final embroidery file in the appropriate format for the target machine.

- Create a production sheet with relevant information (e.g., stitch count, color sequence, special instructions).

Throughout these steps, the use of high-quality embroidery tools can significantly enhance the digitizing process. For instance, MaggieFrame's magnetic embroidery hoops offer superior fabric stability, which is particularly beneficial during the testing phase. Their universal compatibility with various industrial embroidery machines ensures that the digitized designs can be accurately reproduced across different setups, maintaining consistency in the final product.

By meticulously following these steps and leveraging advanced tools like MaggieFrame hoops, embroidery professionals can create stunning, high-quality designs that stand out in the competitive embroidery market.

5.4 Role of Skilled Digitizers

Skilled digitizers are the unsung heroes of the embroidery world, bridging the gap between artistic vision and machine execution. Their expertise is crucial in transforming static artwork into dynamic, stitchable designs that not only capture the essence of the original concept but also optimize it for the embroidery process.

5.4.1 Technical Expertise

Skilled digitizers possess a deep understanding of:

- Embroidery machine capabilities and limitations

- Various stitch types and their applications

- Fabric behavior under different stitch patterns

- Color theory and thread interactions

This technical knowledge allows them to make informed decisions throughout the digitizing process, ensuring the final product meets both aesthetic and functional requirements.

5.4.2 Artistic Interpretation

Beyond technical skills, digitizers bring an artistic sensibility to their work:

- Translating 2D designs into 3D embroidered textures

- Enhancing designs with appropriate stitch directions and patterns

- Adapting artwork to suit the embroidery medium

- Problem-solving to overcome design challenges

Their ability to interpret and enhance designs often elevates the final embroidered product beyond the original artwork.

5.4.3 Efficiency Optimization

Experienced digitizers streamline the embroidery process by:

- Minimizing color changes and jump stitches

- Optimizing stitch counts for faster production without compromising quality

- Creating designs that reduce the likelihood of thread breaks or other production issues

This efficiency not only speeds up production but also contributes to cost-effectiveness and consistency in large-scale embroidery projects.

5.4.4 Quality Control

Digitizers play a crucial role in ensuring the quality of the final product:

- Anticipating and compensating for fabric distortions

- Fine-tuning designs based on test embroideries

- Adapting designs for different fabrics and garment types

Their attention to detail and ability to foresee potential issues result in higher-quality embroidered products with fewer production hiccups.

5.4.5 Continuous Learning and Adaptation

The field of embroidery digitizing is constantly evolving, and skilled digitizers:

- Stay updated with the latest software and machine capabilities

- Adapt to new trends in embroidery design

- Experiment with innovative techniques to push the boundaries of what's possible in embroidery

This commitment to ongoing learning ensures that they can meet the ever-changing demands of the embroidery market.

5.4.6 Collaboration and Communication

Effective digitizers often work closely with:

- Designers to understand the vision behind the artwork

- Production teams to ensure designs are optimized for specific machines and workflows

- Clients to meet specific requirements and expectations

Their ability to communicate technical concepts to non-technical stakeholders is invaluable in achieving successful outcomes.

While the role of skilled digitizers is irreplaceable, their work can be significantly enhanced by using high-quality embroidery tools. For instance, MaggieFrame's magnetic embroidery hoops offer superior fabric stability, which allows digitizers to push the boundaries of design complexity. The universal compatibility of these hoops with various industrial embroidery machines ensures that the digitizers' meticulous work translates consistently across different production setups.

In conclusion, skilled digitizers are the linchpin in the embroidery digitizing process. Their unique blend of technical expertise, artistic sensibility, and problem-solving skills transforms simple artwork into extraordinary embroidered creations. By leveraging their talents alongside advanced tools like MaggieFrame hoops, the embroidery industry continues to evolve, producing ever more intricate and high-quality embroidered products.

6. Choosing the Right Embroidery Digitizing Service

Selecting the appropriate embroidery digitizing service is crucial for achieving high-quality, consistent results in your embroidery projects. This section will guide you through the key factors to consider, compare in-house and outsourced options, evaluate software choices, and highlight how MaggieFrame's innovative products can enhance your digitizing accuracy.

6.1 Factors to Consider When Selecting a Provider

When choosing an embroidery digitizing service, several crucial factors come into play:

6.1.1 Experience and Expertise

Look for providers with a proven track record in the industry. Experienced digitizers understand the nuances of different fabrics, design complexities, and embroidery machine capabilities.

6.1.2 Quality of Work and Portfolio

Review the provider's portfolio to assess the quality and variety of their work. Pay attention to intricate designs, color blending, and stitch quality in their samples.

6.1.3 Turnaround Time and Pricing

Consider your production schedule and budget. While faster turnaround times might be tempting, ensure it doesn't compromise quality. Compare pricing structures, but remember that the cheapest option isn't always the best value.

6.1.4 Customer Service and Communication

Opt for providers who offer clear communication channels and responsive customer service. This ensures smooth collaboration and quick resolution of any issues that may arise.

6.1.5 File Format Compatibility

Ensure the digitizing service can provide files compatible with your embroidery machines. Common formats include .DST, .PES, and .EMB.

6.1.6 Industry-Specific Experience

If you work in a specialized field (e.g., automotive or medical), look for digitizers with relevant industry experience.

6.1.7 Revision Policies

Inquire about their revision policies. A service that offers reasonable revisions can be invaluable in achieving the perfect design.

By carefully considering these factors, you'll be better equipped to choose a digitizing service that meets your specific needs and contributes to the success of your embroidery projects.

6.2 In-House Digitizing vs. Outsourcing

Deciding between in-house digitizing and outsourcing is a significant decision for embroidery businesses. Let's explore the pros and cons of each approach:

6.2.1 In-House Digitizing

Pros:

- Complete control over the digitizing process

- Faster turnaround for urgent projects

- Direct communication between designers and production team

- Ability to make immediate adjustments

Cons:

- High initial investment in software and training

- Ongoing costs for software updates and employee salaries

- Limited expertise compared to specialized services

- Potential for bottlenecks during busy periods

6.2.2 Outsourcing

Pros:

- Access to specialized expertise and advanced technologies

- No need for investment in expensive software or training

- Flexibility to handle fluctuating workloads

- Focus on core business activities

Cons:

- Less control over the digitizing process

- Potential for longer turnaround times

- Communication challenges with external providers

- Dependency on third-party quality control

6.2.3 Cost-Benefit Analysis

When considering the financial aspects:

- In-house digitizing may be more cost-effective for businesses with a high volume of consistent work

- Outsourcing can be more economical for companies with varying workloads or specialized needs

6.2.4 Scalability and Flexibility Considerations

- In-house digitizing offers greater flexibility for last-minute changes

- Outsourcing provides scalability without the need to hire additional staff during busy periods

6.2.5 Hybrid Approach

Some businesses opt for a hybrid model:

- Maintain a small in-house team for quick turnarounds and simple designs

- Outsource complex projects or during peak seasons

When making your decision, consider your business size, workload consistency, types of projects, and long-term growth plans. Remember, investing in quality tools like MaggieFrame's magnetic embroidery hoops can enhance the capabilities of both in-house and outsourced digitizing operations, potentially tipping the scales in favor of bringing more work in-house.

6.3 Evaluating Digitizing Software Options

Choosing the right embroidery digitizing software is crucial for achieving high-quality results. Here's a guide to help you evaluate your options:

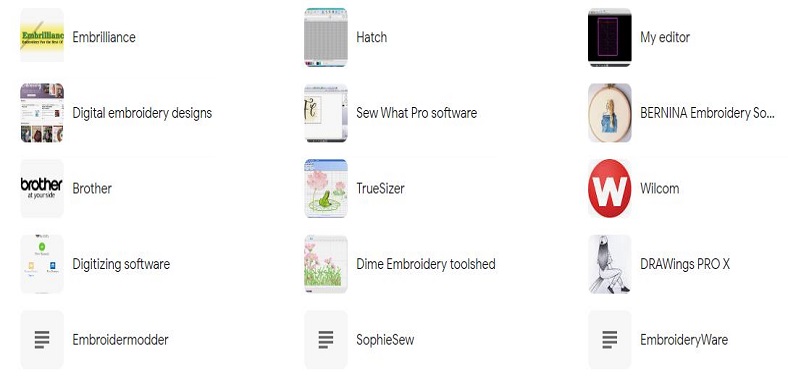

6.3.1 Popular Embroidery Digitizing Software

- Wilcom EmbroideryStudio: Known for its comprehensive features and professional-grade output.

- Hatch Embroidery: User-friendly interface with powerful digitizing capabilities.

- Embrilliance: Offers a range of products for different skill levels and needs.

- Pulse Embroidery: Robust software with advanced digitizing and editing tools.

- Sierra Embroidery Office: Versatile software with a focus on productivity.

6.3.2 Key Features to Look for in Digitizing Software

When evaluating software options, consider these essential features:

- Auto-digitizing capabilities: Ability to convert vector or raster images into stitch files automatically.

- Manual digitizing tools: For precise control over stitch placement and types.

- Stitch editing: Tools for fine-tuning individual stitches or entire sections of a design.

- Thread color management: Accurate color matching and blending capabilities.

- 3D visualization: Preview how designs will look when embroidered.

- Machine format compatibility: Ability to export designs in various file formats for different embroidery machines.

- Lettering tools: Create and manipulate text with embroidery-specific fonts.

- Fabric assistance: Automatic adjustment of stitch settings based on fabric type.

6.3.3 Learning Curve and Training Requirements

Consider the software's learning curve and available training resources:

- User-friendliness: Intuitive interface for beginners vs. advanced features for experts.

- Training materials: Availability of tutorials, user manuals, and online resources.

- Customer support: Access to technical assistance and troubleshooting.

- Community forums: User communities for peer support and knowledge sharing.

6.3.4 Compatibility with Existing Systems

Ensure the software integrates well with your current setup:

- Operating system compatibility: Windows, Mac, or both.

- Hardware requirements: Check if your current computer meets the software's specifications.

- Integration with embroidery machines: Direct connection capabilities with your specific machines.

6.3.5 Scalability and Upgrades

Look for software that can grow with your business:

- Modular structure: Ability to add features as your needs expand.

- Regular updates: Frequency of software updates and new feature releases.

- Upgrade policies: Costs and processes for upgrading to newer versions.

When selecting digitizing software, it's essential to consider how it will work in conjunction with your embroidery equipment. MaggieFrame's magnetic embroidery hoops, for instance, offer superior fabric stability that complements the precision of digitizing software. This synergy between software and hardware ensures that the intricate designs you create are faithfully reproduced in the final embroidered product.

6.4 MaggieFrame's Magnetic Hoops: Enhancing Digitizing Accuracy

MaggieFrame's innovative magnetic embroidery hoops play a crucial role in elevating the accuracy and quality of digitized embroidery designs. Here's how these cutting-edge tools contribute to enhanced digitizing precision:

6.4.1 Superior Fabric Stability

MaggieFrame's magnetic hoops provide unparalleled fabric stability during the embroidery process. This stability is crucial for:

- Maintaining precise stitch placement as designed in the digitizing software

- Reducing fabric distortion, especially in stretchy or delicate materials

- Ensuring consistent tension across the entire embroidery area

6.4.2 Universal Compatibility

One of the standout features of MaggieFrame hoops is their universal compatibility with various industrial embroidery machines. This versatility allows for:

- Consistent results across different machine setups

- Seamless integration into existing workflow systems

- Flexibility in production environments

6.4.3 Improved Design Execution

The enhanced stability offered by MaggieFrame hoops directly translates to better execution of digitized designs:

- Intricate details and fine lines are reproduced more accurately

- Complex fill patterns maintain their integrity throughout the stitching process

- Text and small elements remain crisp and legible

6.4.4 Reduced Error Rates

By minimizing fabric movement and distortion, MaggieFrame hoops help reduce common embroidery errors:

- Fewer instances of misaligned stitches

- Decreased likelihood of thread breaks due to fabric shifting

- Lower rates of design distortion in finished products

6.4.5 Time and Cost Efficiency

The precision offered by MaggieFrame hoops can lead to significant time and cost savings:

- Less time spent on re-hooping and adjustments during production

- Reduced need for design revisions due to execution errors

- Lower rates of product rejection, saving materials and labor costs

6.4.6 Enhancing Digitizer Confidence

When digitizers know their designs will be executed using MaggieFrame hoops, they can:

- Push the boundaries of design complexity with greater confidence

- Incorporate more intricate details and smaller elements into their designs

- Experiment with challenging fabrics and textures

By incorporating MaggieFrame's magnetic embroidery hoops into your production process, you're not just investing in a tool – you're elevating the entire digitizing and embroidery workflow. The enhanced accuracy and stability provided by these hoops ensure that the time and effort invested in creating precise digitized designs pays off in the form of consistently high-quality embroidered products.

7. Best Practices for Embroidery Digitizing

7.1 Preparing Artwork for Digitizing

When it comes to embroidery digitizing, the old adage "garbage in, garbage out" holds true. The quality of your final embroidered product largely depends on the quality of the artwork you start with. Here are some essential steps to prepare your artwork for digitizing:

7.1.1 Choose the Right File Format