1. Introduction

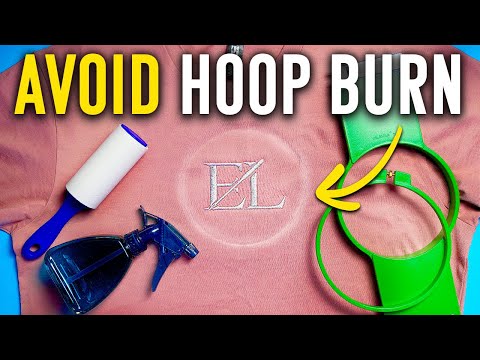

In the vibrant world of machine embroidery, achieving perfection means much more than just selecting the right design; it involves a mastery of tools and techniques. One of the common challenges embroiderers face is "hoop burn"—those vexing marks that can mar your beautifully crafted projects. This article will explore what hoop burn is, delve into its causes, and offer solutions for preventing and removing it. We'll also highlight innovative tools like the MaggieFrame Magnetic Hoops that provide modern solutions to this age-old problem.

2. Understanding Hoop Burn in Machine Embroidery

2.1 What is Hoop Burn?

Hoop burn refers to the unsightly marks or impressions left on fabric following the use of an embroidery hoop. These marks occur when the fabric is tightly sandwiched between the two rings of the hoop, resulting in compressed fibers or even moisture extraction that creates a visible imprint. These marks can range from slight indentations to prominent blemishes that detract from the overall aesthetic of your embroidery.

2.2 Causes of Hoop Burn

The primary cause of hoop burn is excessive pressure from the hoop on the fabric. This pressure can be due to over-tightening, prolonged hooping time, or using poor-quality hoops. It is also exacerbated by the friction and movement during the embroidery process, which can create enough force to damage or imprint the fabric. The quest for a taut and stable fabric often leads embroiderers to tighten their hoops excessively, unwittingly setting the stage for hoop burn.

2.3 Fabrics Most Prone to Hoop Burn

Certain fabrics are more susceptible to hoop burn due to their composition and structure. Delicate fabrics like silk and satin, synthetic materials such as polyester and rayon, and textured fabrics like velvet and terry cloth are particularly vulnerable. These materials can be easily marred by the pressure and friction of traditional hooping methods, highlighting the need for alternative solutions and techniques.

3. Prevention Techniques for Hoop Burn

3.1 Proper Hooping Techniques

To prevent hoop burn, ensuring the correct hooping technique is essential. Always use an appropriately sized hoop for your fabric and design, and adjust the hoop tension so that it is firm but not overly tight. Additionally, you can line your hoop with a thin piece of protective fabric to cushion the primary material, reducing friction.

3.2 Using Appropriate Stabilizers

The right stabilizer can make a significant difference in preventing hoop burn. Choose stabilizers that maintain the fabric's integrity during stitching, such as cutaway or fusible poly mesh stabilizers. These materials help minimize movement and friction, providing a stable base for your embroidery.

3.3 The Floating Method

The floating method is a technique wherein the stabilizer is hooped, and the fabric is loosely adhered to the surface using a temporary adhesive. This method avoids direct contact between the hoop and fabric, reducing the risk of hoop burn. While floating can be a great option for delicate fabrics, it's important to secure the material adequately to prevent shifting during embroidery.

3.4 MaggieFrame Magnetic Hoops: A Modern Solution

MaggieFrame Magnetic Hoops provide an innovative approach to prevent hoop burn by utilizing magnetic force to hold the fabric firmly yet gently. Unlike traditional hoops that rely on pressure and tension, these magnetic frames minimize fabric compression and friction, making them ideal for both delicate and durable fabrics. The seamless integration with a variety of embroidery machines enhances the ease and precision of your projects.

3.5 Masking Fabrics

Masking involves using a protective layer, such as a water-soluble stabilizer or masking film, between the fabric and the hoop. This layer acts as a barrier, protecting the fabric from the hoop's grip while allowing for superb embroidery accuracy. It is especially useful for delicate or specialty fabrics that are prone to marking or distortion.

4. Removing Hoop Burn

4.1 Steaming and Water Spraying

Steam is an effective remedial method for hoop burn, helping relax the fabric fibers. Use a clothing steamer or iron with a steam function to gently treat the affected areas. Alternatively, lightly misting the fabric with water can help the fibers regain their shape and remove shiny marks.

4.2 Laundering Methods

Laundering is another simple yet effective way to remove hoop burn. Washing and drying the fabric can help restore its original texture and appearance, especially for robust materials like cotton or denim. Always follow the fabric's care instructions to avoid damage during this process.

4.3 Vinegar Solution Technique

A diluted white vinegar solution can be used to treat hoop burn. Lightly spray the affected area and, if applicable, iron the fabric to help lift the marks. Test the solution on a small, inconspicuous area first to ensure compatibility with the fabric.

4.4 Using a Lint Brush or Sticky Roller

For fabrics like velvet and terry cloth, a lint brush or sticky roller can be useful in raising the pile and alleviating hoop burn. Gently coax the fibers back into place, and repeat as necessary until the marks dissipate.

4.5 Spray Starch Method

Spray starch can help rejuvenate the fabric's fibers, making it an effective solution for hoop burn. Apply a light coat of spray starch to the affected area and allow it to dry naturally or press with an iron for added rigidity and smoothness.

5. Special Considerations for Different Fabrics

5.1 Delicate Fabrics (Silk, Satin, Organza)

When working with delicate fabrics like silk, satin, and organza, it's crucial to adopt methods that minimize pressure and friction. These fabrics are particularly prone to hoop burn due to their fine fibers and smooth surfaces. Consider using the floating method, where the fabric is secured using a temporary adhesive rather than direct hooping. MaggieFrame Magnetic Hoops can be especially useful here, providing even pressure distribution without compressing sensitive fibers.

5.2 Synthetic Fabrics (Polyester, Rayon)

Synthetic fabrics such as polyester and rayon also require special handling to avoid hoop burn. These materials are often lightweight and can easily display marks from traditional hooping. A magnetic hoop, like MaggieFrame, is ideal as it decreases friction and supports fabric gently yet securely. Additionally, using appropriate stabilizers such as a fusible poly mesh can help maintain fabric stability during embroidery.

5.3 Textured Fabrics (Velvet, Terry Cloth)

Textured fabrics like velvet and terry cloth present their own set of challenges due to their bulk and pile. Hoop burn can manifest as compressed textures, detracting from the fabric's natural appeal. A floating technique or gentle, magnetic hooping methods help maintain the pile’s integrity, preventing compression. MaggieFrame’s magnetic technology is advantageous for these fabrics, ensuring minimal contact and preserving texture.

5.4 How MaggieFrame Adapts to Various Fabric Types

MaggieFrame excels across diverse fabric types due to its innovative magnetic design, which evenly distributes tension and reduces fabric stress. Unlike traditional hoops, MaggieFrame minimizes direct pressure, making it adaptable to both delicate and robust fabrics. This design significantly lowers the risk of hoop burn while enhancing embroidery precision and fabric protection.

6. Advanced Hoop Burn Prevention Techniques

6.1 Using Hooping Stations

Hooping stations can greatly optimize the hooping process, providing a stable platform to prepare fabric and hoop. They ensure consistent tension and alignment, crucial for preventing hoop burn. When combined with MaggieFrame, hooping stations enhance the overall embroidery setup, promoting efficiency and precision.

6.2 Adjusting Machine Settings

Machine settings play a pivotal role in preventing hoop burn. Adjusting the presser foot height and ensuring appropriate stitching speed can mitigate pressure on the fabric. Using MaggieFrame Magnetic Hoops allows for these adjustments by providing a steady hold without additional pressure, thereby preserving fabric quality.

6.3 MaggieFrame's Innovative Design for Reduced Pressure

MaggieFrame’s design uses magnetic forces instead of physical clamps to hold fabrics. This innovation greatly reduces fabric pressure and eliminates hoop burn risks. The magnetic hoops cater to a wide range of fabric types, offering a versatile and reliable solution for maintaining flawless embroidery results.

7. Troubleshooting Common Hoop Burn Issues

7.1 Identifying the Severity of Hoop Burn

Recognizing hoop burn's severity is crucial for determining the right corrective action. Light indentations often respond well to fabric relaxation techniques, such as steaming or water spraying. For more pronounced marks, employing methods like laundering or using a lint brush can be beneficial.

7.2 When to Seek Professional Help

If hoop burn persists despite best efforts, or if the fabric is of significant value or rarity, consulting a textile restoration expert may be prudent. These professionals can provide advanced care solutions that protect fabric integrity.

7.3 MaggieFrame's Customer Support for Hoop Burn Issues

MaggieFrame offers dedicated customer support to address any challenges users may encounter, including hoop burn concerns. Their team provides expert guidance on maximizing the benefits of their magnetic hoops, ensuring optimal fabric care and performance.

8. Comparing Hooping Methods

8.1 Traditional Hoops vs. Magnetic Hoops

Traditional hoops apply tension through physical clamping, often risking hoop burn and fabric deformation. In contrast, magnetic hoops like MaggieFrame utilize gentle magnetic force, offering a less invasive solution that prevents hoop burn and facilitates smoother operation across fabric types.8.2 Cost-Effectiveness of MaggieFrame Magnetic Hoops

Despite their advanced technology and ease of use, MaggieFrame Magnetic Hoops offer a cost-effective solution compared to traditional methods. Their durability and reduction in fabric damage translate to long-term savings, making them a superior choice for both hobbyists and professionals.8.3 User Testimonials and Case Studies

Users consistently report improved embroidery outcomes and reduced incidence of hoop burn when using MaggieFrame. Case studies highlight significant enhancements in fabric handling and embroidery efficiency, underscoring the product’s value in various crafting and professional contexts.9. Conclusion

Embarking on your embroidery journey means navigating the vibrant tapestry of techniques and tools at your disposal, and overcoming challenges like hoop burn is part of this enriching process. By understanding its causes and mastering prevention methods, you can safeguard your fabric and enhance the quality of your creations. The innovative MaggieFrame Magnetic Hoops stand out as a modern solution, seamlessly integrating with various machines to minimize friction and pressure, thus effectively preventing hoop burn. With these insights and tools, you're well-equipped to produce flawless embroideries that truly showcase your talent and creativity.